An Open E-Bike Kit

Motivation and the Idea:

As part of my internship at Fablab Amsterdam I will work on a project of my own. For this I chose to make an add-on E-bike kit, following the open design concept. I came to this idea after moving to the Netherlands and using a bike as daily transport for the first time. The cheapness and effectiveness of the bicycle are clear as is it’s lesser environmental impact vs the car. I started to look in to electric options and found many different companies, each with their own solutions which are often incompatible with each other. I also found the E-bikes to be quite expensive. This lead me to have a look at kits to convert my existing bike to electric power. These kits are less expensive, but they require varying levels of disassembling and modifying your bike. Many of the affordable kits use hub motors which add weight to the wheels of the bike which affect handling and braking negatively.

Integrated e-bike example:

Giant Explore-E_-1-STA

Image source

Image source

Mid drive kit example: Bafang mid drive conversion

Hub drive kit example: Rear wheel hub drive conversion

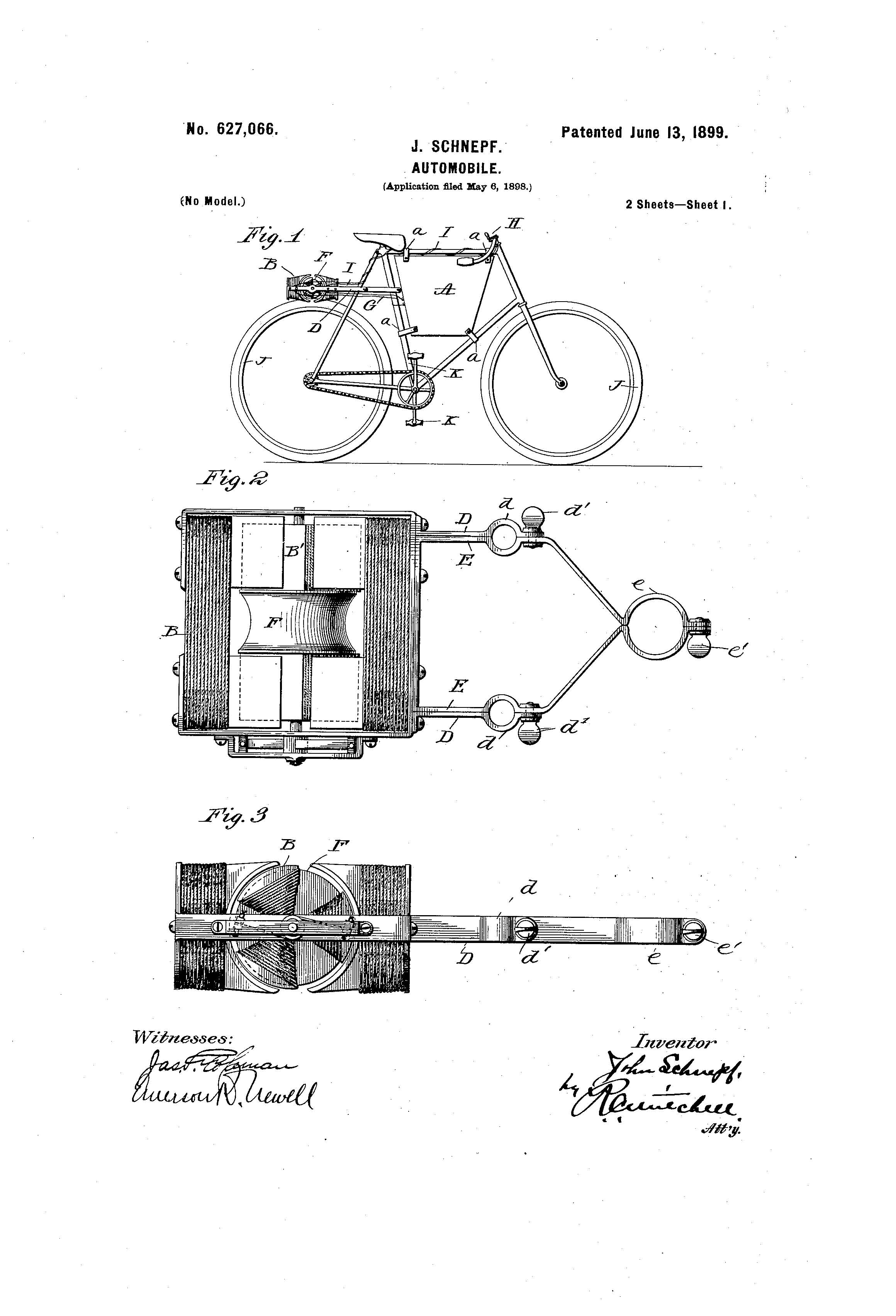

I eventually found another form of conversion kit which seemed more like what I was looking for: friction drive. This method uses a spinning wheel (or the outside of the motor bell itself) in direct contact with the tyre to transfer power via friction. I like the simplicity of this method with its few components and opportunity to be made small, light and easily removable. This is known as a friction drive system and has been around since some of the first electric bikes:

1899-06-13 US627066A U.S. patent e-bike:

The friction drive kits I found which have been launching lately have good range, speed, are small and can attach to almost any bike. However, I still haven’t seen one with what I would consider an accessible price. There is one product I have seen by Semcom, who website reads “SMART ENGINE TURNS ANY BIKE ELECTRIC”. It says it will cost less than 100 euro but at the time of writing it’s not available to consumers.

Semcom friction drive:

The D.I.Y. community online provides various examples of friction drives which interest me more as inspiration for this project.

Myself and the majority of bike riders need an e-bike for the simple purpose of getting from A to B faster, this is the value they give us. Extra features and software are far less important to the average rider but the industry markets their bikes based on small differences in specifications or things like different colours instead of providing the base, practical option that is needed. The parts needed to make a friction drive are few and readily available. I think this makes it a good opportunity for an open design project to succeed here. There have been other D.I.Y. friction drive projects, some of which I have found in my research. This project will focus, in particular, on accessibility (in price, materials and the skills needed to build and install) and practicality (meeting most people’s needs).

D.I.Y. Projects:

Bicycle BoosterPack

Kepler’s friction drive

Hillhaters Mk 3

Project Outline:

What?: A small, easily removable electric engine to convert bikes in to e-bikes and scooters into e-scooters, created to fit with the open design principle. The kit will use friction drive where brushless motor(s) in contact with the bike tyre propel the bike forward. I think I can design something which can be mounted at various different places on the bike. I will have to research to find the mounting points on the bikes frame which are the most common across the many bike configurations out there.

It should be cheap and able to be made with readily available materials with little experience. Safety during use and the charging of the batteries will also be an important consideration.

Why?: To increase accessibility to e-bikes for the public, whose needs are not being met by the private industry. A practical, durable and cheap conversion kit could help people who currently can’t afford one. Converting the bikes we already have is a better option for the environment than producing entirely new, integrated e-bikes. I think the simplicity of the friction drive method means that there is a large group who could hypothetically make their own.

How?: I will use desk and field research as well as prototyping and testing in the course of my project. I will try to find questions in my desk research which will inform my observations and interviews.

For whom?:

Right now I think I will focus on two versions, dictated by the builder’s access to tools, materials and the required skills. One will be the Fablab version, with full open hardware and software and designed for manufacture at a Fablab. The other will be aimed toward those with little technical skill, using whatever mix of off the shelf/ custom parts is needed to make a good quality product.

University students are a natural user group and could form groups to cheaply convert bikes in each university.

Traditional e-bike customers who also have the necessary skills are also a potential group.

Educators could also use the kit and the instructions for lessons.

Prototypes Timeline:

P1: Basic version + testing

P2: P1 with mounting + control improvements

P3: ESC programming

P4: DIY ESC PCB for Fablab version

P5: Fablab version mounting 1.0

P6: Simple open scooter to work with kit

Other Tasks:

Documentation

Instructions

Key Points: Low barrier to entry, accessible Convenient, practical Standard parts, Open Design Repairable, maintainable, Simple

Expectations: I think it’s likely I will run out of time before I finish what I would like to do with this project. I don’t mind though, This is the kind of project that I can continue to work on and document at university. I expect to run into the problem friction drives have with wet conditions (slipping) and the current spike when starting from a complete stop. I am inexperienced in coding and electronics so those kind of tasks could end up taking up a lot of my time.

Next Steps: My next step will be to continue my desk research and further define the priorities for the kit. Order the parts for the first prototype. Then I’ll start finding references from various sources.